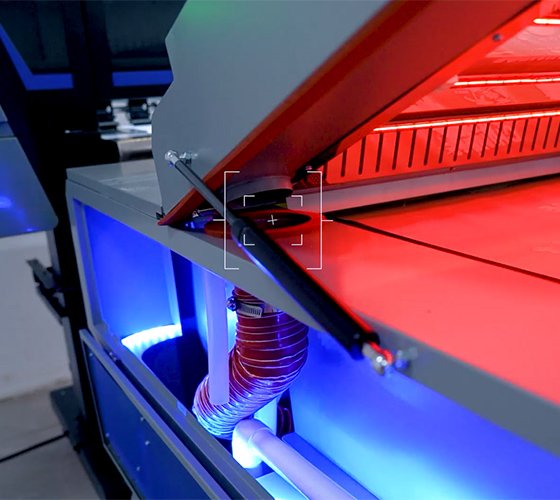

The new powderless DTF printer (no powder DTF printer) uses glue instead of powder, which is more environmentally friendly. It is a printing solution that solves all the needs of clothing manufacturers and designers. It is an artifact to help business expansion.

Printhead QTY : 3/4

Printhead: EPSON I3200-A1

3 Head Printing Speed: 4pass: 7.5sqm/h; 6pass: 5sqm/h; 8pass: 4sqm/h

4 Head Printing Speed: 4pass: 15sqm/h; 6pass: 10sqm/h; 8pass: 8sqm/h

Max Print Width: 680mm

Color: 5 colors+glue (C, M, Y, K, W+G)

RIP Software: maintop, photoprint, CADlink (optional)

Product Specification

| Product | Powderless DTF printer |

| Model | SINO-604P |

| Printhead | EPSON I3200-A1 |

| Printhead QTY | 3/4 |

| Printing Speed | Output (sqm/h) |

| 3 Heads Printing Speed | 4pass:7.5sqm/h ; 6pass:5sqm/h ; 8pass:4sqm/h |

| 4 Heads Printing Speed | 4pass:15sqm/h ; 6pass:10sqm/h ; 8pass:8sqm/h |

| Max Media Width | 730mm/28.74″ |

| Max Print Width | 680mm/26.77″ |

| Ink Type | Waterbased pigment ink |

| Color | 5 colors+glue (C, M, Y, K, W+G) |

| Ink Supply System | Continuous ink supply system |

| White Ink Cycle | Equipped |

| Media Type | Powderless PET film |

| Media Thickness | 1mm |

| Heating System | Intelligent heating & drying system |

| Feed & Take-up System | Equipped |

| Capping & Moisturizing | Auto capping system & moisturizing system |

| RIP Software | Maintop, photoprint, CADlink (optional) |

| Input Power | AC110V/220V, 50HZ/60HZ, 350W-8KW |

| Working Environment | Temperature: 18-32℃, humidity: 46-65% |

| Printer Size | 1850*795*1600mm, 172kgs |

| Dryer Size | 2305*1092*1100mm, 270kgs |

| Printer Packing Size | 2060*890*790mm, 217kgs/1.45cbm |

| Dryer Packing Size | 2400*1120*1136mm, 330kgs/3.05cbm |

Product Main Features

The upgraded oil drain port can collect waste oil produced by printing and solve the problem of its flowing everywhere.

Multiple operating languages can be selected to meet the printing needs of different countries.

Independent suction control front and rear mesh belt platform to ensure the printing process is smooth and stable.

The white ink is continuously circulated and stirred to avoid damage to the nozzle and extend its service life.

Product Advantages

Without excessive powder, the ink adheres more firmly to the printable surface, and the print is more stretchable and flexible.

Eliminating powder smear allows ink to transfer more clearly, enhancing the color vibrancy and clarity of printed graphics

Replacing the traditional powder mode with glue reduces smoke production and is more environmentally friendly.

No need to shake powder, the printing process is simpler, and the printing speed is 20% higher than before.

Product Applications