*We respect your confidentiality and all information is protected.

Requires DTF printer, DTF ink, PET film, and DTF hot-melt powder to be used together.

The printhead used in our Kingjet DTF printer is EPSON I3200A1 and all of our printhead is original and brand new.

Any fabric which can stand 170℃ heat press temperature can be transferred by DTF, like cotton, T-shirts, jeans, canvas, sweatshirts, polyester, etc.

Print cost for 1 sqm transfer fabric pattern is about 1-2 USD, and about 0.07-0.1usd for A4 size Printing.

If print 1 sqm pet film pattern, it needs the following consumables: CMYK(total 4 color): 10-15ml;white:15-30ml;powder:10-20g

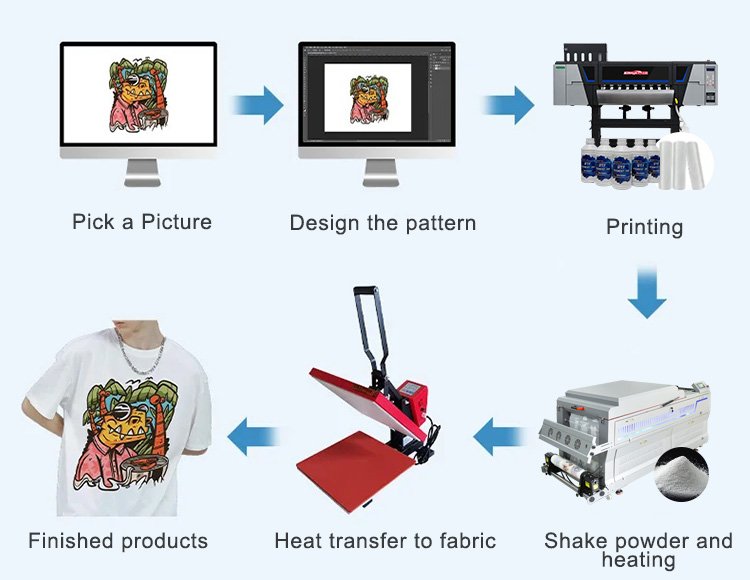

Print the designed pattern on the PET film, then evenly sprinkle hot melt powder on the pattern, melt it at high temperature and then dry it, cut the PET film, and heat-press the pattern onto various types of clothing through heat press, and then you can complete the clothing printing!

DTF printer is mainly for garment printing and the uv dtf printer is mainly for hard and irregular items, like cups, phone case, bottle, metal, plastic etc.

UV DTF (Direct to Film) printing involves applying UV-cured ink directly onto a special film, which is then transferred onto various substrates. The durability and scratch resistance of UV DTF prints depend on several factors:

Ink Quality: UV-cured inks are generally more durable than solvent-based or water-based inks because they cure (harden) when exposed to UV light. This curing process creates a tough, scratch-resistant surface.

Substrate: The material onto which the UV DTF print is transferred also plays a crucial role. Smooth, non-porous surfaces like glass or acrylic tend to support better adhesion and scratch resistance compared to rougher or flexible materials.

Finishing: Applying a clear coat or protective laminate over the UV DTF print can significantly enhance scratch resistance. This additional layer acts as a sacrificial barrier, absorbing scratches and protecting the underlying print.

Handling: Proper handling and care of printed items can prevent scratching. Abrasive materials or harsh cleaning agents can damage the surface, regardless of the printing method.

In summary, UV DTF printing generally provides good durability and scratch resistance, especially when compared to traditional printing methods. However, the specific resilience against scratches can vary based on ink quality, substrate, and additional protective measures taken after printing.

The market prospect of UV DTF is very huge for the following reasons:

UV DTF (Direct to Film) printing requires several key components and equipment to produce high-quality prints. Here’s a list of what is typically needed for UV DTF printing:

UV Printer: A UV printer equipped with UV-curable inks and UV lamps is essential. This printer allows for direct printing onto the special DTF film.

DTF Film: Specialized DTF film or transfer sheets designed for UV printing. These films have a coating that allows them to accept UV-cured inks and adhere to various substrates.

UV-Cured Inks: UV-curable inks that are compatible with the UV printer. These inks harden (cure) when exposed to UV light, creating a durable print.

UV Curing Unit: UV lamps or LED UV curing system integrated into or adjacent to the UV printer. These lamps cure the UV ink immediately after it is printed onto the DTF film.

RIP Software: Raster Image Processor (RIP) software tailored for UV printing. This software manages color profiles, image placement, and other printing parameters.

After transferring UV DTF prints onto items, such as garments or other substrates, their durability and washability depend on several factors:

Quality of Transfer: Properly transferred UV DTF prints can be quite durable. The adhesion between the transferred print and the substrate is critical. If the transfer is done correctly and adheres well, it can withstand washing and wear.

Substrate Compatibility: The type of substrate onto which the UV DTF print is transferred affects its longevity. For textiles, the substrate’s material and weave, as well as the ink used, influence how well the print withstands washing and stretching.

Washing Instructions: Following the manufacturer’s washing instructions is crucial for maintaining the print’s integrity. Typically, UV DTF prints can withstand gentle washing with mild detergents. Avoiding harsh chemicals and high-temperature wash cycles helps preserve the print.

UV Ink Quality: UV-curable inks used in DTF printing are generally durable and can withstand washing to varying degrees depending on the specific ink formulation and curing process.

Additional Protection: Applying a clear protective coating over the transferred UV DTF print can enhance its durability and resistance to washing and abrasion.

In general, UV DTF prints can be washable and durable if the transfer process is performed correctly and the appropriate substrates and inks are used. However, exact longevity can vary based on the factors mentioned above. It’s advisable to conduct tests and follow recommended care instructions to maximize the lifespan of UV DTF printed items.

We supply ink and film too, which can be matched with our printer perfectly. It is recommended to buy with the machine.

WhatsApp us