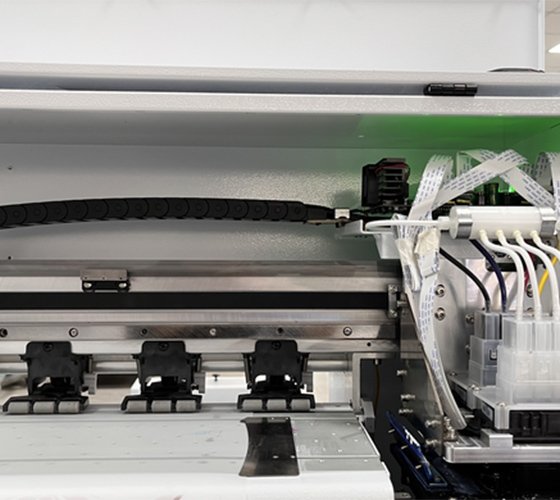

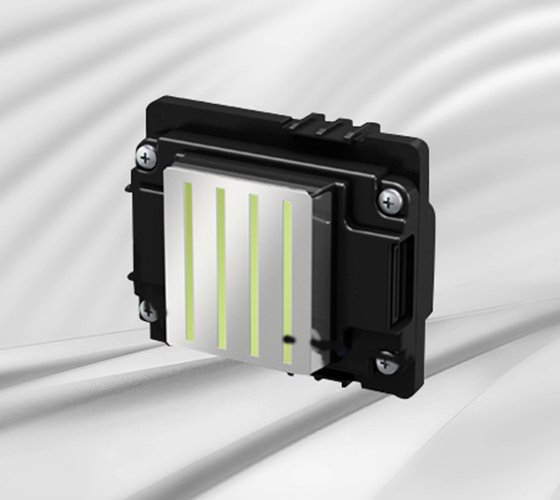

The DTF printer with good economical and stable performance is equipped with EPSON XP600 print head, which is lower in cost than the I3200 A1 print head, greatly reducing the printing start-up cost.

Printhead: 2*epson xp600(Default);2*epson i3200A1(Optional) ; 2*epson i1600A1 (Optional)

Printing Speed: 4pass:5sqm/h, 6pass:4sqm/h; 4pass:12sqm/h,6pass:9sqm/h ; 4pass:6sqm/h, 6pass:5sqm/h

Max Print Width: 420mm

Color: 5 colors (C, M, Y, K, W)

RIP Software: maintop, photoprint, CADlink

Product Specification

| Product | SINO-302A DTF printer | ||

| Model | SINO-302A | ||

| Printhead | 2*EPSON XP600 (Default) | 2*EPSON I1600A1 (Optional) | 2*EPSON I3200A1 (Optional) |

| 4pass: 5sqm/h, 6pass: 4sqm/h | 4pass: 6sqm/h, 6pass: 5sqm/h | 4pass: 12sqm/h, 6pass: 9sqm/h | |

| Color | 5 colors (C, M, Y, K, W) | ||

| Max Media Width | 430mm | ||

| Max Print Width | 420mm | ||

| Ink Type | Waterbased pigment ink | ||

| Media Type | PET film | ||

| Heating System | Intelligent embedded heating system & powder melt machine | ||

| Feed & Take up System | Equipped | ||

| Ink system | Automatic ink supply white ink circulating and stirring | ||

| Clamp | Combined anti-warping clamps | ||

| Power Electric Supply | 110V/220V,50-60HZ | ||

| Power | 350W-3400W | ||

| RIP Software | Maintop,photoprint,CADlink(optional) | ||

| Working Environment | Temperature: 18-32℃ , humidity: 46-65% | ||

| Printer Size | 1100*510*625mm, 70kg | ||

| Shacker Size | 800*510*510mm, 50kg | ||

| Packing Size | Printer: 1320*730*850mm, 105.5kg , 0.480cbm Shaker: 880*610*730mm, 70kg , 0.440cbm | ||

Product Main Features

Maintain the continuous flow of ink and prevent nozzle clogging to achieve uninterrupted production.

Automatically adjust the printing height during the printing process to avoid collision or damage to the nozzle.

Keep the printing flatness at 0-0.5mm, making the printing surface flatter and printing accuracy higher.

Apply even pressure to eliminate wrinkles on the material surface and make the printing surface smoother.

Product Advantages

Equipped with Epson XP600 Head,it greatly reduces starting costs since its lower cost than I3200 A1 heads.Good choice for beginning.

The automatic take-up system saves the time and energy of manually adjusting printing materials, making it more convenient and efficient.

The machine is equipped with a 42cm printing width, which perfectly adapts to A2 size printing needs and meets personalized customization requirements.

The DTF ink used is green and environmentally friendly, making printing more sustainable.

Product Applications