Supports 9-colors printing with fluorescent colors, meeting the needs of personalized, batch printing, and multi-color printing of T-shirts and hoodies.

Printhead: 4*epson I3200-A1

Printing Speed: 4pass:30sqm/h ; 6pass:20sqm/h ; 8pass:16sqm/h

Max Print Width: 680mm

Color: C, M, Y, K, W (RGBO and neon colors available)

RIP Software: maintop, photoprint, CADlink (optional)

Product Specification

| Product | SINO-604 DTF printer |

| Model | SINO-604 |

| Printhead | 4*EPSON I3200-A1 |

| Printing Speed | Output (sqm/h) |

| 4 Pass | 30sqm/h |

| 6 Pass | 20sqm/h |

| 8 Pass | 16sqm/h |

| Max Media Width | 730mm |

| Max Print Width | 680mm |

| Ink Type | Waterbased pigment ink |

| Color | C, M, Y, K, W (RGBO and neon colors available) |

| Ink Supply System | Continuous ink supply system |

| White Ink Cycle | Equipped |

| Media Type | PET film |

| Heating System | Intelligent embedded heating system & powder melt machine |

| Feed & Take up System | Equipped |

| Capping & Moisturizing | Auto capping system & moisturizing system |

| RIP Software | Maintop, photoprint, CADlink (optional) |

| Input Power | AC110V/220V, 50HZ/60HZ, 350W-4000W |

| Working Environment | Temperature : 18-32℃ , humidity : 46-65% |

| Machine Size | Printer: 1850*795*1600mm, 172kg ; shaker: 2305*1092*110mm, 270kg |

| Packing Size | Printer: 2060*890*790mm, 217kg , 1.448cbm ; shaker: 2400*1120*1136mm, 330kg , 2.830cbm |

Product Main Features

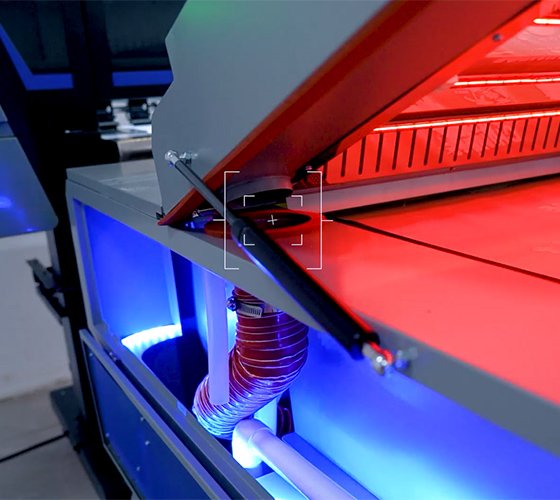

Smoke purifier and sealed circulating powder shaking environment to solve the problem of flying powder.

White ink circulation system ensures smooth delivery of ink to the print head and prevents clogging of the print head.

Low noise and reduced friction between various parts of the machine make printing more stable and long-lasting.

Realize automatic system cleaning, anti-clogging flash spray and moisturizing functions.

Product Advantages

In addition to C, M, Y, K and W colors, you can also choose RGBO and neon colors to meet the printing needs of different colors.

Intelligent digital control screen with multiple operating languages available to meet various working environments.

Upgrade the oil drain port to automatically collect waste oil and solve the problem of oil stains flowing everywhere.

The machine has been upgraded with higher printing accuracy, faster drying and better printing quality.

Product Applications